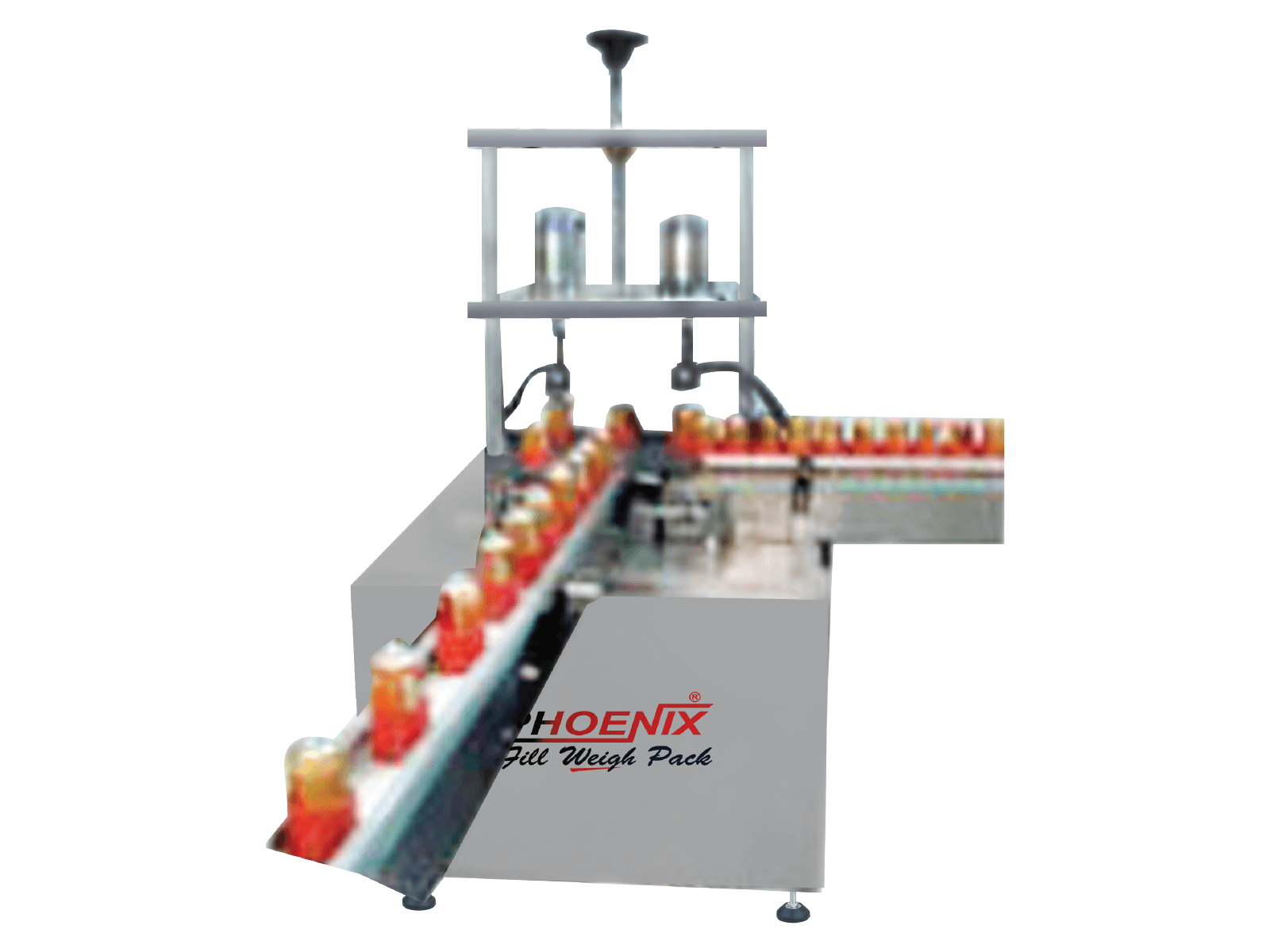

GASSING UNIT

- This unit consist two Pneumatic indexing table with two turrets both units operates simultaneously.

- After Crimping diversion unit is placed on conveyor which leaves equal amount of cans into both indexing units.

- After Crimping the cans pass to Gassing unit through Radius Conveyor, Gassing unit operates through complete Pneumatic system.

- Turrets operates by Pneumatic Indexer, at required indexing stations gassings heads are placed which operates when can sense the roller vale.

- Gassing head fill the required amount of gas into the cans through booster pump and the amount of gas filling is adjustable.

- The amount of gas is filled to the can is equally distributed to all heads, i.e. amount of gas is divided by number of nozzles.

Description

| Technical Specifications | |

| Output | 100 to 120 CPM [Depending on filling quantity] |

| Non Return Valve | both end External Threading 1/2 B.S.P |

| Non Return Ball Valve | both end External Threading 1/2 B.S.P |

| Chain | MOC: Delrin/Acetal |

| Turret | MOC: PVC, 8 Pocket |

| Feed Height | 900mm, plus minus 50mm. |

| Overall Dimensions | 1200mm widthX1500mm depthX2000 mm height |

| Control Panel | Pneumatic |

| Dimensions | 800mm heightX600mm widthX300mm deep, 2 Nos. |

| Contact Parts | SS / Alluminium /PVC |

| Non Contact Parts | MS, Hard chrome , Electroplated , Powder Coated, Spray Painted |

| Power Consumption | 0.75 K.W. |

| Air Consumption | 55 to 57 C.FM. |

| Air Pressure | 7 to 8 bar |

Reviews

There are no reviews yet.