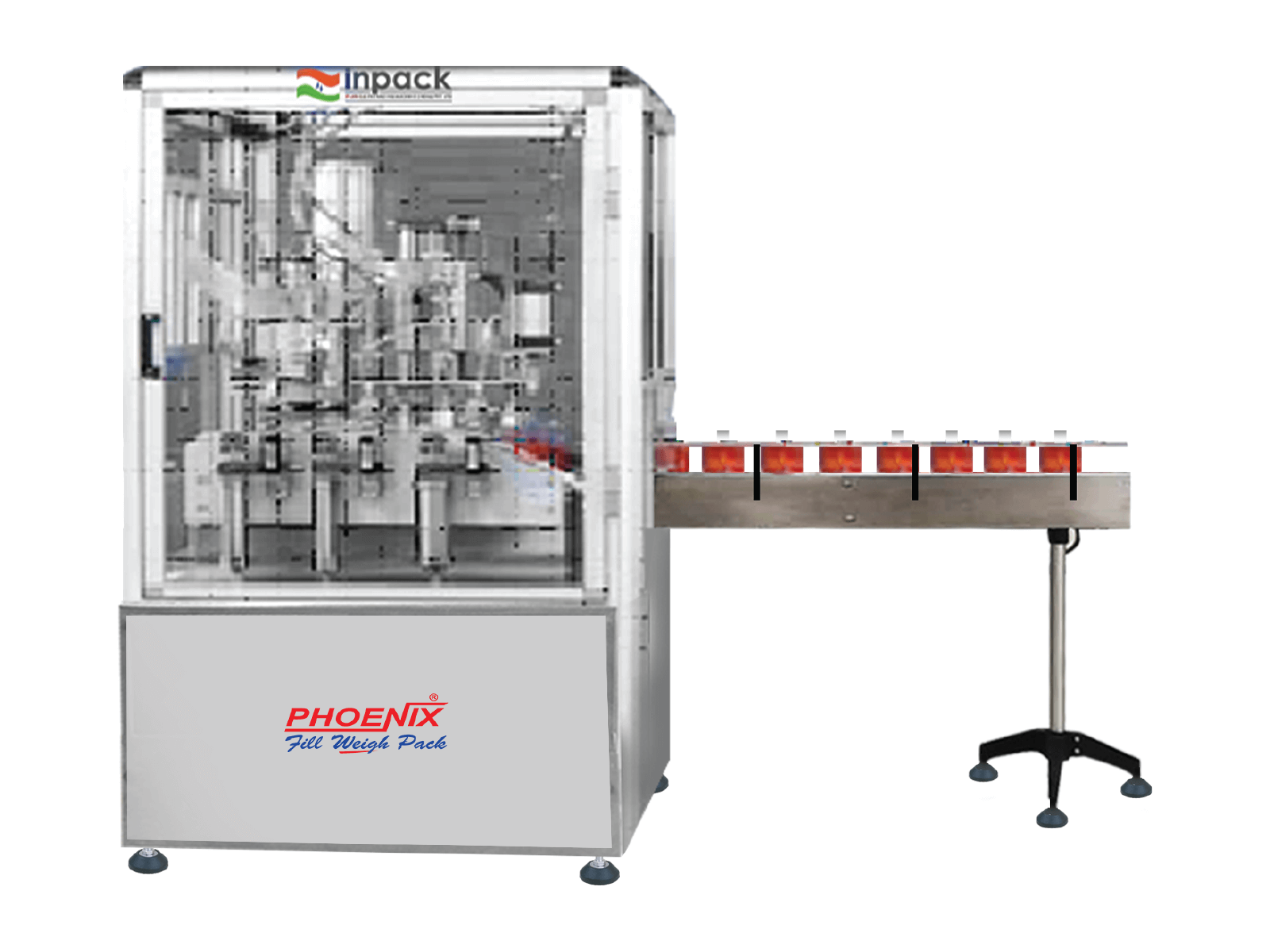

SEMI AUTOMATIC PERFUME FILLING, CRIMPING & COLLAR FITTING MACHINE

- There will be 4 filling head.

- Manual placement of the bottle into adjustable pucks (we cannot assure all the shape and sizes of the bottle to accommodate in the same pucks, additional pucks may be required depending on the bottles shapes and sizes).

- The motors to drive the main machine and the conveyor will be flame proof.

- Fixture for setting bottle holder on pucks: The pucks having locator on the bottom fits on the locator pin on the unit.

- Adjustable pucks: The pucks will be adjustable type. There will be round base with two nos. holders for holding the different shapes of the bottles. The holders move on the slots provided on the bottom and easily locked with the help of knobs provided.

- Manually place the spay pump.

- Manually place the collar head.

Description

About:

The intake and expelling features positioned parallel on the same side leaving maximum inner space in order to carry out a high number of operations. The bottle is moved by a closed circuit conveyor belt. LA1 be integrated into existing line. Machine set up is open to custom requirement.

| Technical Specification | |

| Filling capacity | 50-200 ml |

| Production speed | 1000 to 1500 pcs/hr |

| Power supply | 380V, 3 phase |

| Installed power | 1 kW |

| Air required | 8CFM @ 6bar pressure |

Reviews

There are no reviews yet.