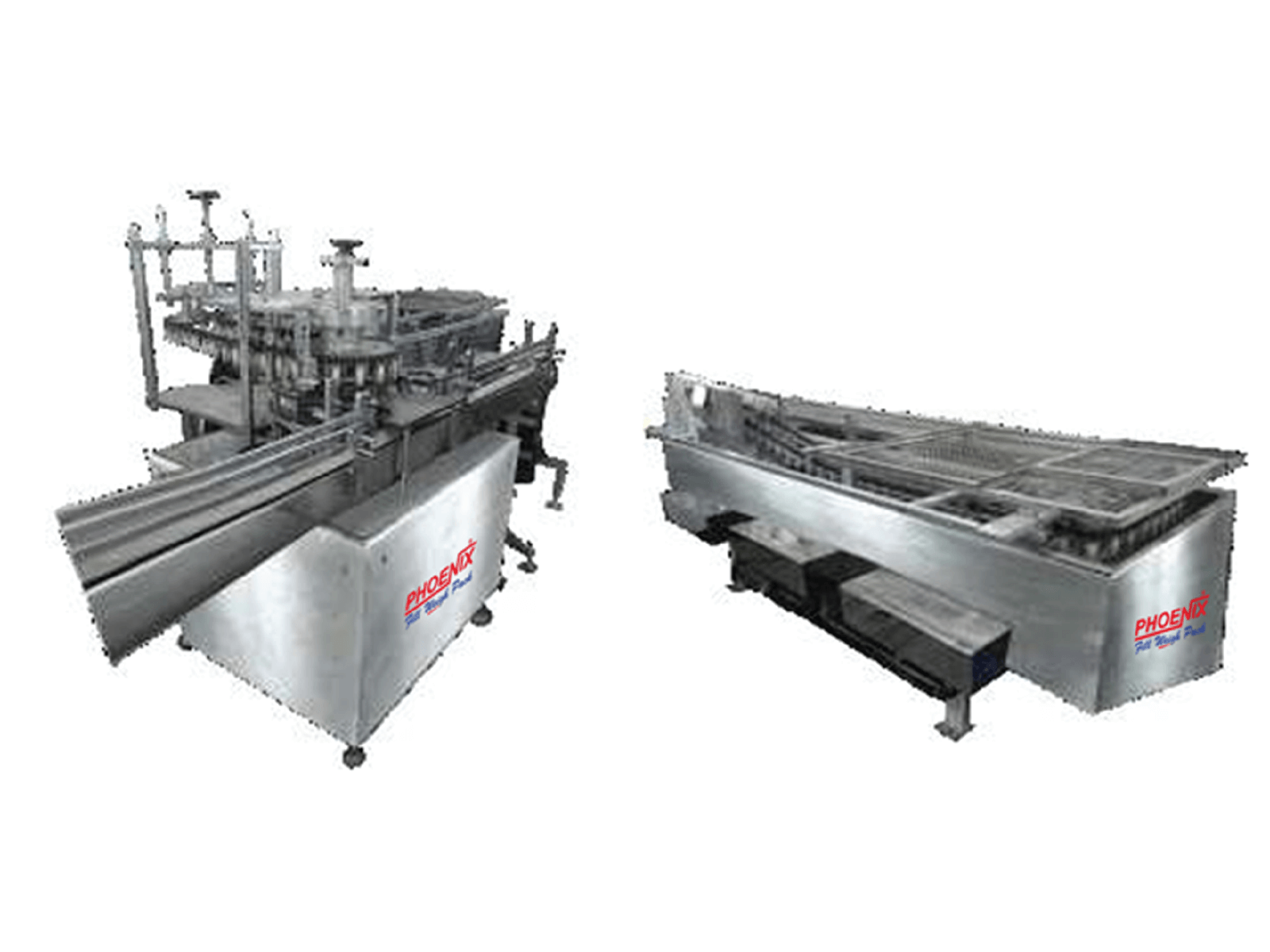

WATER BATH

- After coding cans pass to the input turret of water bath unit, this is a rotary unit contains main turret and one input as well as output turret.

- While cans moving in input turret an arrangement has provided by which Grippers will hold the cans and carries cans to the water tank for leak testing purpose.

- Holders are placed at required pitch and mounted in chain, this chain moving continuously inside the tank.

- The routing of the chain is designed in such a way that can is dipped inside the water up to 180 seconds.

- After leak checking cans will be dropped at output turret, this turret transfers the cans to the output conveyor.

Description

| Technical Specifications | |

| Output | Up to 120 CPM |

| Control Panel | Electrical for water bath unit / FLP Panel for water tank |

| Contact Parts | SS / Alluminium /PVC |

| Non Contact Parts | MS, Hard chrome , Electroplated , Powder Coated, Spray Painted |

| Feed Height | 900mm, plus minus 50mm. |

| Overall Dimensions | 6600mm widthX2600mm widthX1750 mm height |

| Power Consumption water bath unit | 3 K.W. |

| Total Power consumption | 75 K.W |

| Air Consumption | 10 C.FM. |

| Air Pressure | 7 to 8 bar |

| MOC of tank | SS304 |

| Top Guard | SS wire mesh |

| Heaters | FLP, 5 K.W, 15numbers |

| Total Power Consumption | 78 K.W |

| Control Panel | FLP |

| Temperature Controller | Digital with PID action |

| Maximum Temperature | 75 deg. |

| Required Temperature | 55 deg. |

| Water Circulation Pump | 1.5 H.P |

| Water Displacement | 120 ltr/min |

| Pressure | 2kg/cm sq |

| Connection | 1 ½” B.S.P |

| Leak Testing Time | 150 to 180 seconds |

| Dimensions of panel | 620X420X220 |

Reviews

There are no reviews yet.